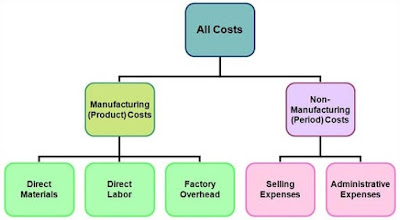

A manufacturing company incurs both manufacturing costs (also called product costs) and non-manufacturing costs or expenses (also called selling and administrative expenses). In the illustration below you can see the difference between manufacturing and non-manufacturing costs and their classification:

Manufacturing vs. non-manufacturing costs

Let us review these types of manufacturing and non-manufacturing costs in more detail.

Manufacturing costs and their classification

Manufacturing costs are the costs that a company incurs in producing a product.

From the managerial accounting standpoint, there are three types of manufacturing costs:

-Direct materials

-Direct labor

-Factory (or manufacturing) overhead

1. Direct materials as a type of manufacturing costs

Direct materials are raw materials that become an integral part of the finished goods.

Direct materials always have a variable nature. Variable costs change in proportion to production. For example, the company purchases metal parts (raw material) to produce valves. The more valves are produced, the more parts Company has to acquire. Therefore, parts have a variable nature; the amount of raw materials bought and used changes in direct proportion to the amount of valves created. For this Company, other direct materials would include, for example, plastic parts and paint.

Different manufacturing companies will have different direct material costs depending on the types of finished goods they produce. The table below provides a few examples:

Examples of direct material costs

Publishing company- Paper, ink, book covers

Automobile manufacturer- Tires, automobile metal parts

Computer manufacturer- Hard drives, monitors

From this you can see that direct materials are the integral part and a significant portion of finished goods.

2. Direct labor as a type of manufacturing costs

Almost any production plant or factory requires employees to operate equipment, move raw materials from the warehouse to equipment, and so on. These employees are directly involved in the production process and the cost of their remuneration and benefits represents direct labor:

Direct labor is the cost of wages to be paid to individuals who work on specific products or in other words, the cost of wages of employees who are directly involved in converting raw materials into finished goods.

Usually direct labor is a variable cost. In most situations the amount of direct labor required is directly correlated with the amount of finished goods produced. For example, wages and related benefits of employees who operate machinery to produce valves represent direct labor costs for a Company. The more valves are to be produced, the more employees will be required to operate machinery, paint, assemble, etc.

Direct materials and direct labor, when added together, represent the prime cost. Direct materials and direct labor are called prime costs because they are directly (physically, "primarily") associated with the finished goods production.

3. Factory overhead as a type of manufacturing costs

Factory overhead is any manufacturing cost that is not direct materials or direct labor.

Factory overhead can have variable or fixed nature, depending on whether overhead changes in direct proportion with production volumes. The following are some examples of factory overhead costs:

Variable Factory Overhead Examples

-Electricity

-Heating

-Water

-Indirect Materials

-Indirect Labor

Fixed Factory Overhead Examples

-Depreciation

-Property taxes

-Property insurance

-Salaries for non-production employees

Most items in the list above are self-explanatory, so they don't require further explanation, while indirect materials and labor may benefit from further explication.

Indirect materials are materials that are (a) not an integral (physical) part of the finished goods, or (b) a minor part of the finished goods to be economically traced to the finished good or have a very small physical association with the finished product.

For example, a Company would treat the following costs as indirect materials: oil lubricants and light bulbs used in manufacturing equipment, package boxes, wrenches, etc.

Other companies will have different types of indirect materials depending on their manufacturing processes. The table below provides a few examples:

Examples of indirect materials cost (overhead cost)

Publishing company- Glue, printing press lubricants

Automobile manufacturer- Factory light bulbs, drill bits

Computer manufacturer- Assembly line lubricants, screwdrivers, polishers

As you can see form the list, indirect materials are an insignificant portion or not an integral part of the finished goods.

Indirect labor is the cost of production employees who are involved in the manufacturing process, but do not work on a specific product.

For example, wages of custodians, maintenance people, supplies room supervisors, etc. are considered indirect labor.

Direct labor and factory overhead, when added together, represent the conversion cost. Direct labor and factory overhead are called conversion costs because they are involved in converting raw materials into finished goods.

The image below shows the relationship between direct materials, direct labor, overhead, prime cost, and conversion cost:

This is the relationship between direct materials, direct labor, overhead, prime cost and conversion cost.

No comments:

Post a Comment